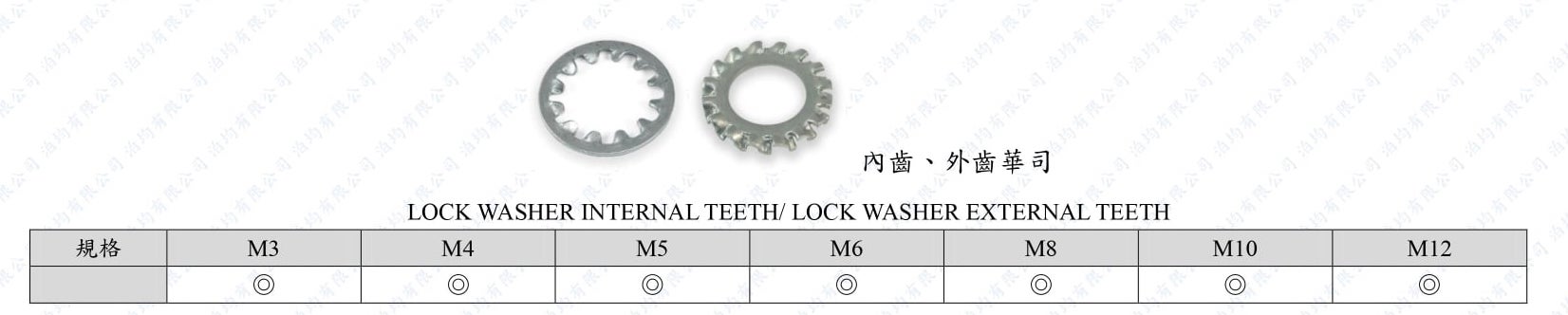

Lock Washer Internal Teeth/ Lock Washer External Teeth

Lock washers with internal and external teeth are essential hardware components designed to prevent loosening or vibrations in fastened connections. These specialized washers play a crucial role in maintaining the integrity and stability of assemblies in various industries.

Lock washers with internal teeth feature teeth or serrations on the inside surface, creating friction between the washer, the fastener, and the surface. This design resists rotation and prevents the fastener from coming loose due to vibrations or movement. These washers are commonly used in applications where a secure connection is vital, such as machinery, automotive, and industrial equipment.

Lock washers with external teeth, on the other hand, have teeth or serrations on the outside surface. When tightened against the fastener and surface, the teeth bite into the material, creating resistance to rotation and minimizing the risk of loosening. These washers are suitable for applications where a strong grip is necessary, such as heavy machinery and structural components.

Both types of lock washers are manufactured from various materials, including steel, stainless steel, and zinc-coated options, to provide different levels of corrosion resistance and strength.